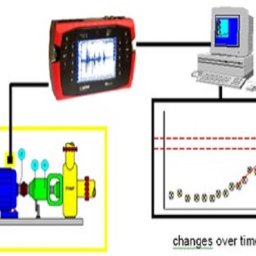

A vibration analyzer is used for testing and inspection in manufacturing production facilities, product development laboratories, construction sites and more. A vibration analyzer measures vibration for the preventative maintenance of manufacturing equipment. A vibration analyzer also is used to assess a machine’s axis of rotation. If there is rotating unbalance, the rotor may be exchanged during a scheduled downtime of the machine.

Measurements obtained by a vibration analyzer typically identify parameters of v ibration acceleration, vibration velocity and vibration displacement. In this way, vibration is recorded with great precision. Portable vibration analyzer devices provide accuracy and mobility, allowing for vibration measurements to be taken effectively and conveniently in the field. Many vibration analyzer products feature memories for storing vibration measurment data for further analysis.

ibration acceleration, vibration velocity and vibration displacement. In this way, vibration is recorded with great precision. Portable vibration analyzer devices provide accuracy and mobility, allowing for vibration measurements to be taken effectively and conveniently in the field. Many vibration analyzer products feature memories for storing vibration measurment data for further analysis.

When possible, a manufacturer’s calibration certificate is included with each vibration analyzer offered by PCE Instruments. For an additional fee, most vibration analyzer devices can be calibrated to ISO standards at the time of purchase, allowing you to include these vibration analyzers in your set of internal quality tools and calibrate the devices regularly to ensure precision. See the accessories tab of each vibration analyzer product to learn more about ISO-certified calibration.

The vibration analyzer is an irreplaceable tool for the professional on the job. Every vibration analyzer can carry out the demanding task regardless of the technical problem at hand. It is also possible to perform an acoustic vibration evaluation with a sound pressure level meter (for the analysis of vibration frequency). Critical frequencies that can cause damage or create disturbing noise levels may be detected.