Infrared Scanning of electrical installations falls under classification of Predictive Maintenance Fault Finding. The value is that we are now able to predict an electrical fault before the element fails completely.

We are able to get this due to the heat build-up of any electrical element under stress and predict that it will fail while it is still functional and appears normal to the naked eye or any other test equipment. The heat signature identified with the use of an Infrared camera. The pictures are then analyzed and put into an easy-to-follow report so that they can rectify before a breakdown occurs, preventing loss of production due to unplanned down time.

Unexpected breakdowns in electrical supply can inconvenient and costly. Infrared electrical thermography is

a useful tool that can recognize stressed elements of your electrical installation before they break down or cause a fire. This gives you the opportunity to solve the problem as part of planned maintenance before it causes a serious problem.

Another result of failed or stressed electrical elements is the risk of fire; in fact the risk is more real than commonly realise. It is in this vein that insurance companies are increasingly calling for infrared electrical thermography surveys as a valuable risk

assessment aid.

In the past this service was only available to very large companies and mining houses due to the cost determinant, but as with everything there have been massive advancements in the last few years and Thermo Scanning has now become a very profitable tool in the small to medium size business world.

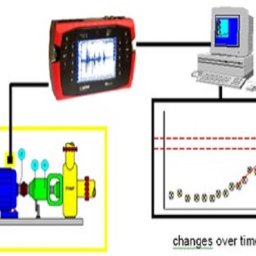

Maintenance includes vibration analysis on machines, audio, ultrasonic and infrared thermography inspection on electrical systems. Thermography used to recognize equipment hot spots. This task is typically carried out using temperature sensing instruments like thermocouple sensors or other forms of thermometers. Limitation of this analysis is that this kind of instrument can give maintenance personnel only with temperature readings on certain spots but not overall electrical system.

Thermography inspection generally uses infrared instrumentation to scan and create a temperature profile of intended targets.

In a typical manufacturing plant, Infrared thermography inspections did on electrical systems such as electrical switchboards, high-voltage distribution equipment motors, corresponding controllers, transformers and other control panels.

Switchgear Thermography

A great deal of investment is presently being made installation of thermal viewing ports for switchgear. These ports allow infrared inspections to carry out without removing switchgear covers, thus it would avoid worker arc-flash exposure. Installation of permanent infrared sensors and continuous infrared monitors are also reasonable methods for recognizing potential thermal failures of critical equipment. The principle of outdoor switchgear assemblies is often compromised by defective strip heaters. The strip heaters increase the switchgear temperature slightly above ambient to prevent condensation during daily or seasonal temperature changes. Functionality of these strips heaters and their effectiveness to carry out this duty can decide by carrying out thermal imaging of the switchgear enclosures. In other words, and once again, absence of heating identifies a potential problem.

Benefits of Thermography Survey

A major insurance carrier estimates that nearly 25 percent of all electrical failures attributed to faulty electrical connections. Therefore, many insurance firms are the driving force behind requiring facilities to conduct annual infrared surveys. Infrared technology has evolved into one of the most effective technologies for preventing failures and added benefit of not requiring an outage to carry out, as it can done on raw. Several further benefits of infrared technology listed below:

Hot spots such as loose connections and bad contacts.

- Under-rated cables overheating under existing demand.

- Unbalanced loads.

- Stressed earth leakage units, circuit breakers, conductors and other electrical elements.

Infrared Electrical Thermography Survey Benefits

An infrared electrical thermography survey can result in significant financial savings for the client by:

- Reducing the risk of an electrical fire.

- Reducing the risk of an unplanned electrical outage.

- Identifying priorities for planned maintenance, resulting in your spend going where it needed most.

- Determines if the elements and system have been properly installed and are not damaged

- Reduces downtime

- Reduces risk of equipment failure

- Increases safety

- Improves insurability

- Reduces liability exposure of the designers and installers

- Improves system performance

- Determines elements and systems carry out properly and meet the design intent

- Determines if elements and systems compliance with the project specifications and design

- Reduces construction schedule delays

- Saves money

Infrared Thermography Testing can be Done on

- Detecting loose or corroded electrical connections

- Detecting electrical unbalance and overloads

- Inspecting bearings and Electrical motors

- Inspecting steam systems IR Imaging helps better to recognise and report suspect elements

- Enable the repair to done right the first time.

- High resistance connections

- Hot spots

- Over loaded cables

- Over loaded fuses or breakers

- Imminent motor or conveyor bearing failure

- Motor windings over heating

- Overheating in distribution equipment

- Phase load imbalance

- Hot spots in high level lighting

- Heat build-up in overcrowded trunking

- Thermal insulation breakdown (hot or cold)

- Thermal loss

- Damp ingress