Studies show that over 85% of disruptive failures in high voltage (HV) and medium voltage (MV) equipment are Partial Discharge related. Partial Discharge action ultimately leads to failure. Our PD testing service does not require shutdown and is the best way to plan maintenance, repair or replacement activities in a cost effective and efficient way.

Following the partial discharge survey a comprehensive PD Test report is issued. This report details any problems found and also any recommendations corresponding to these problems.

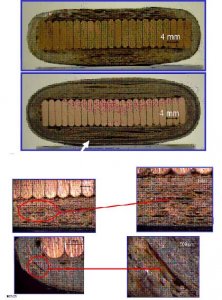

Examples of damage to the insulation by partial discharge

WHAT IS PARTIAL DISCHARGE?

A partial discharge (PD) is an electrical discharge or spark that bridges a small portion of the insulation between two conducting electrodes. Partial Discharge can happen at any point in the insulation system, where the electric field strength exceeds the breakdown strength of that portion of the insulating material. Partial Discharge can occur across the surface of insulating material (mainly due to contaminants or irregularities), within gas bubbles in liquid insulation, in voids within solid insulation or around an electrode in gas (corona activity).

PARTIAL DISCHARGE EMISSIONS

Partial Discharges emit energy as:

Electromagnetic emissions, in the form of radio waves, light and heat

Acoustic emissions, in the audible and ultrasonic ranges

Ozone and nitrous oxide gases

Partial Discharge activity provides evidence that an asset is deteriorating in a way that is very likely to lead to failure. The process of deterioration can propagate and increase, until the insulation is no longer able to withstand the electrical stress therefore leading to flashover. The ultimate failure of HV/MV assets is often sudden and disastrous, leading to massive damage and network outages.

DETECTING PARTIAL DISCHARGE

We use two technologies for detecting partial discharge, namely:

Ultrasound for surface discharge

Ultrasound detection of surface discharge is a well-established worldwide methodology. Ultrasound detection of discharge relies on detecting the sound emissions given off by the discharge. The sound energy from is a discharge centred on a frequency spectrum above the range of the human ear. Therefore instruments are used to move the frequency to a comfortable audible frequency and present it in headphones and measure the intensity of a simple scale.

TEV for internal discharge

TEV detection of internal detection was first developed by EA Technology 25 years ago. It is well established in the UK with increasing recognition around the world. TEV detection relies on the voltage pulses that are created on the surrounding metalwork when there is a partial discharge within the insulation. These are detected on the outside surface of the surrounding earthed metalwork using capacitive coupling.

INTERPRETATION OF RESULTS

One of the benefits of using our Partial Discharge Testing Service is our ability and experience at interpreting the results. The interpretation of results is aided by the use of EA Technology’s partial discharge measurements database that contains over 20,000 records of surveys of switchgear using partial discharge detection equipment. A judgement has been made that readings which would appear in the top 5% in the database for switchgear imply that the switchgear requires further investigation. It is possible to interrogate the database to determine the criteria for further investigation of different subsets within the data e.g. for particular types of switchgear, different voltage ratings, particular manufacturers etc. The level for further investigation of ultrasonic measurements is determined more by the knowledge that a source has been found than by the amplitude of the measurement. This is because the amplitude is very dependent on the size of the opening through which the airborne ultrasonic signal can pass and a clear direct line path between the source and the opening. A source is deemed to be found if movement of the ultrasonic microphone across the opening and angling the probe towards and away from the opening shows that the source is within the switchgear.

It is important that the following additional criteria are taken into consideration. Any one of these factors may result in a further investigation being carried out at levels below the general criteria.

Switchgear component

History of failures

Circuit importance

Level of Risk

If you require further information on Partial Discharge or require a Partial Discharge Survey, please contact us, we would be delighted to answer any queries you might have.